FUTURE OF LIBRARY STORAGE

High-Density Storage Solution

A Cost Effective and Space-Saving Storage Solution for today’s evolving Libraries

Today large-scale institutions are challenged to find innovative solutions to preserve the library collections for long-term while using minimum space for storage. AMASTEC offers fully automated library solutions that increase your valuable library space to be used for other purposes, reduce overall cost, minimize workload, and sustainable solution that meet your preservation requirements.

Advantages

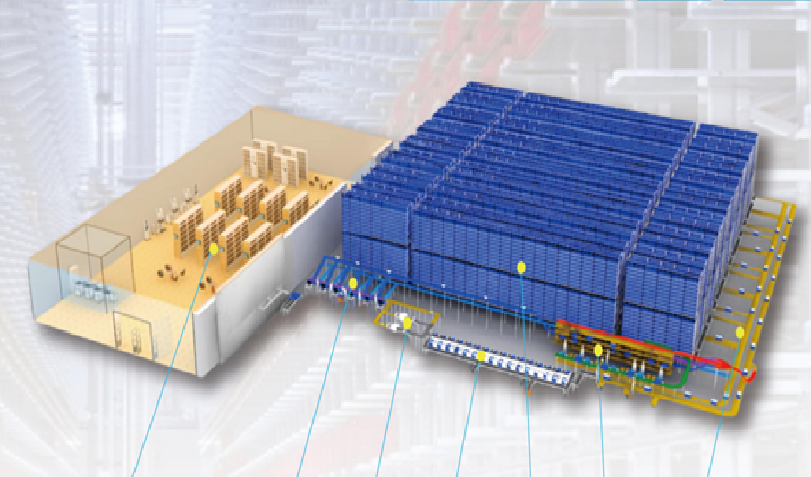

High Bay Shelving System

How it works ?

In high-density automated shelving systems, all items have their barcodes and placed in the barcoded bins. Each item is scanned whenever it is removed or returned back to the bin. This allows the library management software to record the location of all stored items and helps in rapid storage and retrieval.

Returned items from circulation are collected at a check-in location. The system of library determines whether these items are stored on open shelves or automated storage shelves. For an item to be returned to the automated storage shelf, operator scans its barcode, and the ASRS stacker crane bring the correct bin. The operator places the item into the bin, and the ASRS crane returns the bin to its storage location.

Similarly, to request an item from the storage, a patron simply uses the library ordering system, ASRS shuttle brings the correct bin to a central location where an operator takes the requested item from the bin and then deliver to the patron. The bin is then returned to the rack. The inventory control system can be programmed to optimize retrieval times by loading more frequently used items into bins closer to the central location to reduce retrieval time.